Pulp and Paper Industry Trends

1. Increased Online Sales

The online sales of pulp and paper products is growing in the United States and China, which are the biggest markets. This is a trend that is expected to continue in 2020. It’s partly due to online shopping that has required innovation in packaging to optimize the display of products on shelves. The growth encompasses a higher demand for raw materials and corrugated boxes. There is also an increase in the number of products that are required immediately with very little lead time. This includes both same-day and next-day product delivery services. From a production standpoint, the goal is to provide services faster without sacrificing quality.

2. Higher Packaging Demand

In 2020, the global demand for various types of packaging products will either remain stable or increase. This includes production in Japan, China, European countries and the United States. In fact, one of the strengths of the pulp and paper industry is the fact that the demand for packaging products is always expanding. This is spurred by the boost in online shopping and the explosion of e-commerce entrepreneurial endeavors in recent years.

3. Use of Big Data

Another trend that’s in play in the pulp and paper industry is the use of big data. This is for the purpose of analyzing industry trends and needs to optimize the results of production, marketing and sales. There’s also the use of new technologies, including intelligent systems and connected devices during the production process for improved outcomes. The capabilities will continue to develop, such as smart systems that assess the condition and quality of pulp and paper products. Analytics are even used for the purpose of assessing the volume and growth of trees that can be harvested for raw materials. The use of big data is expected to expand in 2020 and subsequent years.

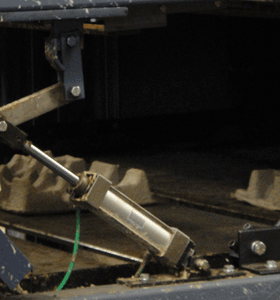

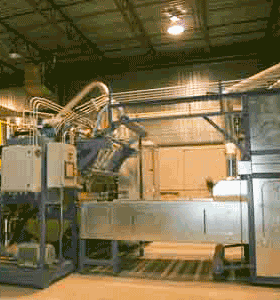

4. Digital Revolution

Although the digital revolution did not destroy the pulp and paper industry, it did require a pivot in strategy. For instance, there was a clear shift to packaging materials from print paper, for reasons that are obvious given the tremendous demands associated with shipping products purchased online. Many in the industry have made tactical moves that involved leveraging capabilities to meet the changing needs in the market. There has also been the implementation of new technologies for the purpose of optimizing productivity. The result is often faster speed and improved quality.

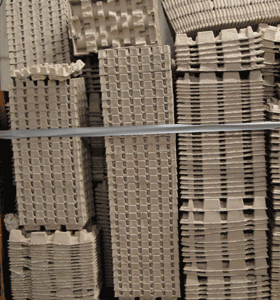

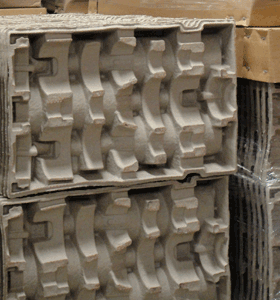

5. Lightweight Packaging

If you’re a consumer, you may have noticed a change in the weight of certain packaging. To those that are attentive, this becomes obvious for certain products. It’s because lightweight packaging was introduced as many benefits were discovered. This is the case for packaging products at all levels, including luxury brands. One of the benefits of lightweight packaging is that it can support the growth of a business by cutting expenses. Lightweight packaging lowers pulp expenses, reduces CO2 emissions and slashes shipping costs, which are just some of the many benefits.

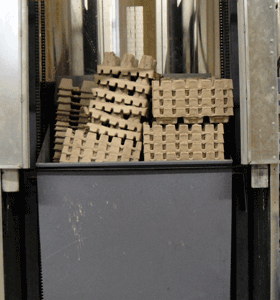

6. Recyclable Products

The ability to recycle pulp and paper products is non-negotiable for some consumers. As a result, there is an increase in recyclable products. This has been a challenge in that some products contained coatings that were waterproof and problematic for recycling. Now there is a push to use protective coatings that are recyclable and it’s a trend that will further develop in 2020 and beyond. The growing concern over the amount of packaging that could not be recycled has resulted in the involvement of the European Union in the area of plastic packaging. This offers many future opportunities for pulp and paper.

7. Hygiene Products Packaging

Another trend that will continue in the pulp and paper industry is the increasing growth of hygiene product and the subsequent need for packaging. This includes toilet paper, wipes, tissues and paper towels, to name a few. The growth is partly due to the increased purchase of these items by the middle class. In some regions of the world, this is attributed to an actual increase in the middle class population and thus an increase in the consumption of these products. Manufacturers in the pulp and paper industry have exploited this growth in socioeconomic status by producing packaging that accommodates an increasing demand.

8. Thermal Market Growth

There is growth in the thermal market that’s linked to the increase in food deliver services. Specifically, there is an increase in the number of restaurants that offer delivery options and also an explosion of third-party delivery service providers, such as GrubHub and UberEats. This has created a need for thermal packaging that is expected to grow. As long as consumers expect to have hot food delivered to their home expeditiously, there will be a thriving thermal market in pulp and paper. There are many possibilities and opportunities in this area that will emerge as e-commerce continues to evolve.

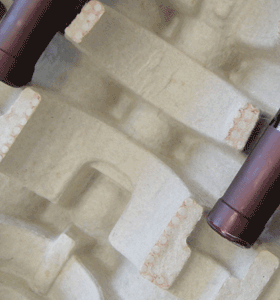

9. Packaging for Food

Packaging for food seems to be in constant development. In recent years, there has been an increasing interest in packaging products that are resistant to grease. This type of product is currently used for a wide variety of packaged good and in restaurants. The materials used to produce packaging that’s resistant to grease is changing in an effort to eliminate fluorochemicals and replace it with a natural option that doesn’t contain any chemicals. Manufacturers will continue to innovate and evolve in this area to accommodate regulations and meet the current industry demands.

10. Anti-Plastic Sentiments

There are on-going efforts to reduce or eliminate the use of plastic for packaging. This anti-plastic sentiment is beneficial to the pulp and paper industry in that it encourages biodegradable alternatives. In fact, the use of plant-based raw materials is being explored. This is being driven by governmental agencies and by consumers that are health conscious and committed to finding eco-friendly options. Simply put, the problems associated with plastic result in a tremendous number of opportunities in the pulp and paper industry. The development of alternative products will continue into 2020 and beyond, especially as it relates to the banning of single-use plastic products.

Pulp and paper will continue to play a major role in the world. Despite the changes that have occurred because of technological advancements, this is an industry that has thrived and will continue to do so in 2020. In fact, the digital revolution of recent years has led to an expansion in the pulp and paper industry. As the world continues to evolve, so will the industry. Check out the information below where you’ll find statistics related to pulp and paper industry trends.